I-Wire yeDitya yokusika iDitya ikwabizwa ngokuba kukudityaniswa kwetekhnoloji yokusika. Kukusetyenziswa kwe-elektroplating okanye i-resin yendlela yokuhambisa idayimani idityaniswe kumphezulu we-wire yentsimbi, intambo yedayimani ngokuthe ngqo kumphezulu we-selicon rod okanye i-silicon ingot ukuvelisa ukugaya, ukufezekisa iziphumo zokusika. Ukusika intambo yedayimani kuneempawu zesantya esingqongqo sokucheba, ukunqunyulwa okuphezulu kunye nokulahleka okuphantsi.

Okwangoku, imakethi enye ye-crystal ye-wire yedayimani yokusika i-selicon wafeer imkelwe ngokupheleleyo, kodwa ikwadibene nenkqubo yokukhuthaza, phakathi kwe-velvet imhlophe yeyona ngxaki ixhaphakileyo. Ngenxa yoku, eli phepha ligxile kwindlela yokuthintela i-wire yedayimane yokusika i-monocrystalline ye-velvet yengxaki emhlophe.

Inkqubo yokucoca ye-wire yedayimani yokusika i-monocystalline wafer kukususa isixhobo se-selicon wasike isixhobo esivela kwipleyithi yomatshini, susa umtya werabha, kwaye ucoce i-silicon wafer. Izixhobo zokucoca ikakhulu umatshini wokucoca (umatshini wokucoca) kunye nomatshini wokucoca. Eyona nkqubo icocekileyo yoomatshini abacocekileyo zezi: Ukutyibilika-ukuCwangciswa kwe-Sprassonic ukucoca-ukucoca amanzi acocekileyo. Inkqubo ephambili yokucoca yomatshini wokucoca yile: ukutya okusungula-amanzi amnyama-i-rinsing rinsing rinsing-alkali yokuhlamba-i-alkali yokuhlamba amanzi-ecocekileyo) -Ukunyusa kancinci.

Umgaqo we-crystat ye-velvet yodwa

I-Monocrystalline ye-Silicon ye-Swicon ye-Wingelo lophawu lwe-Anisotropic Sorrosion ye-Monocrystalline ye-Silicoltal wafer. UmGaqonkqubo wokuphendula yile ndlela ilandelayo yeChemical Reance:

Si + 2naeh + H2O = na2sio3 + 2h2 ↑

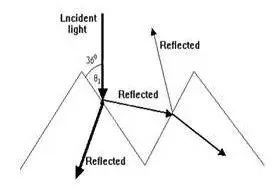

Eyona nto ibalulekileyo, inkqubo ye-suede yi: I-Naoh yesicombululo seressosion ye-corrosion yomhlaba ohlukeneyo, (100), isantya se-terstal ye-terstal, (111), i-monocy sokocy safer ye-anisotrystalline, ekugqibeleni yabekwa phezu komhlaba . Emva kokuba kwenziwe isakhiwo, xa ukukhanya kuyinto yesehlo kwi-piramidi kwi-engile ethile, ukukhanya kuya kubonakala kwithambeka kwelinye icala, oko kufanelekileyo, ngaloo ndlela kuncitshiswa, ngaloo ndlela kuncitshiswe i-accountical bafer , oko kukuthi, isiphumo sokukhanya kwetrap (jonga umfanekiso 2). Uhlobo olungcono kunye nokufana kwendlela "yePiramidi", eyona nto icacileyo yetrap, kunye nokuthoba umphezulu we-silicon wafer.

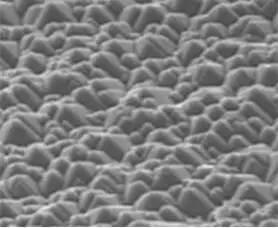

Umzobo 1: I-Micromorphology ye-monocrystalline sefen wafer emva kwemveliso ye-Alkali

Umzobo 2: Umgaqo-nkqubo wokukhanya we "PYIRAD"

Uhlalutyo lwe-whitering enye ye-crystal

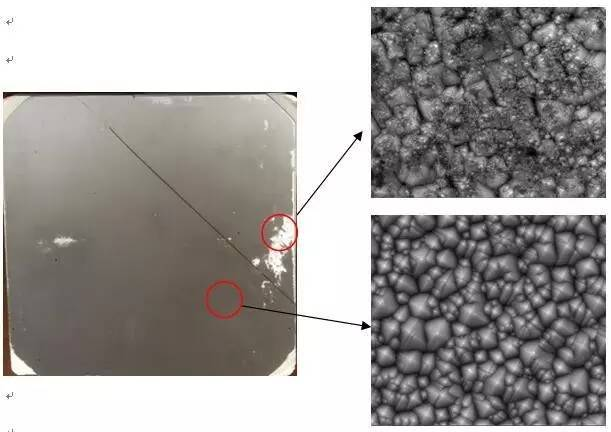

Ngokuskena i-microscope ye-elektroni ye-White Silicon, kwafunyaniswa ukuba iphiramidi ye-proerst ye-White Wafer kule ndawo yayingayi kwenziwa khona, kwaye umphezulu wawubonakala ngathi unepiramidi ye-suede Kwindawo emhlophe ye-selicon enye ye-selicon yasenziwa ngcono (jonga umfanekiso 3). Ukuba kukho intsalela kumphezulu we-monocrystalline, umphezulu uza kuba nendawo eshiyekileyo ye-Permob "iPiramid" isakhiwo kunye nesiphumo esiqhelekileyo sendawo esihlala kuyo singaphezulu kwendawo eqhelekileyo, indawo enengxaki ephezulu ngokuthelekiswa nendawo eqhelekileyo ekubonakaliswe emhlophe. Njengoko kunokubonwa ukusuka kubume bokusasazwa kwendawo emhlophe, ayikho rhoqo okanye isebenza rhoqo kwindawo enkulu, kodwa kuphela kwiindawo zasekhaya. Kufanele ukuba ukuba i-Pill Shotluals kumphezulu we-silicon wafer ayicoci, okanye imeko yomphezulu we-silicon wafer ibangelwa lungcoliseko lwesibini.

Umzobo 3: Ukuthelekiswa kweMicrosoft Microstation yomahluko kwi-velvet ye-velvet ye-sefirs

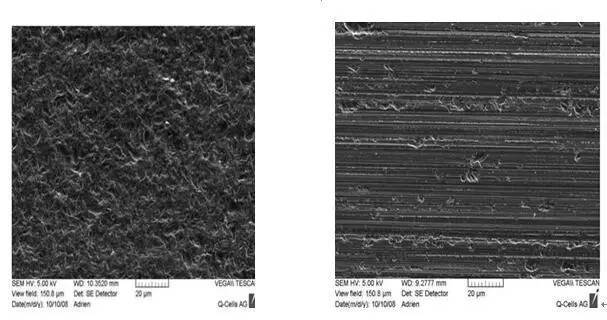

Umphezulu we-wire yedayimani esisikizi se-silicon wafer igudileyo kwaye umonakalo mncinci (njengoko kubonisiwe kumzobo 4). Xa kuthelekiswa nodaka lwesilicon wafer, isantya sokuphendula se-alkali kunye ne-wire yedayimani esisiken ye-Silicon Wicon Alfer, ngoko ke impembelelo ye-velvet icacile kakhulu.

Umzobo 4: (a) I-Micrografitha ye-Micrografic Cafu i-Swicon Wafer (b) i-Micrografi yoWire yeDayimane ye-Willicon ye-Silicon Wafer

Owona mthombo uphambili we-wire-cut wire-cut sefen waffer

. Ulwelo olusika ngentsebenzo ogqibeleleyo lunokunqunyanyiswa kakuhle, ukusasazeka kunye nobuchule bokucoca ngokulula. I-surfacapes ihlala ineepropathi ezingcono ze-hydrophilic, ekulula ukuyicoca kwinkqubo yokucoca isilicon wayife. Ukuphefumla okuqhubekayo nokujikeleza kwezi ntengiso emanzini kuya kuvelisa inani elikhulu lamagwebu, oko kukhokelela ekwehliseni ukuhamba okupholileyo, kuchaphazela ingxaki enkulu, kunye neengxaki eziphezulu kwaye zichaphazela kakubi ukusetyenziswa. Ke ngoko, ipholoji ihlala isetyenziswa kunye nearhente yokufaka. Ukuze kuqinisekiswe ukusebenza ngokungagungqiyo, i-silicone yemveli kunye nePolyteher zihlala zihlwempuzekile. Isinyibilikisi emanzini kulula kakhulu ukuba i-adferb kwaye ihlale kumphezulu we-silicon wafer kwingxaki yendawo emhlophe. Kwaye ayihambelani kakuhle nezinto eziphambili ze-uthotho, ke, kufuneka zenziwe zibe zizinto ezimbini, izinto eziphambili kunye neearhente zokungakhathali zongezwa emanzini, kwinkqubo yokusetyenziswa, ayikwazi ukulawula i Sebenzisa kunye ne-dosage yeearhente zanga-Antifoam, zinokuvumela i-overdose yearhente yokwamkelwa, ekhokelela kwintsalela ye-Silicon Wafer, nangona kunjalo, ngenxa ye-arhente ephantsi Izixhobo, ke, uninzi lwendawo epholileyo yasekhaya zonke zisebenzisa le fomula; Enye into epholileyo isebenzisa iarhente yokufaka i-Doffieng, inokuhambelana nezixhobo eziphambili, akukho songezelelo, inokulawula ukusetyenziswa kwayo ngokufanelekileyo, ukusetyenziswa kwenkqubo efanelekileyo kakhulu, yayo Iintsalela zinokulawulwa kumanqanaba asezantsi kakhulu, eJapan kunye nabavelisi abambalwa basekhaya bamkela le nkqubo yefomula, ngenxa yendleko zayo eziphezulu zexabiso, inzuzo yamaxabiso ayibonakali.

. ucingo sele luqalisile ukusika kwi-suble yerabha kunye neplate ye-resin, kuba iBhodi yeSilicon i-Gein i-Epoxy Relin i-Epoxy i-Epoxy Relin, indawo yokuthambisa i-Epoxy iphakathi kwendawo yerabha okanye i-resin Iplate iphantsi, inokubuya ngokulula ngexesha lokusika kwaye ibangele ukuba ithole kwaye inyibilike, iqhotyoshelwe kwi-wire yentsimbi kunye ne-selicon ye-silicon ye-selicon kunye ne-seficon ye-selicon ifunyenwe kwaye Ifakwe i-resin, xa iqhotyoshelwe, kunzima ukuhlamba, ungcoliseko olunjalo lwenzeka kufutshane nomda we-silicon wafer.

. kunye ne-wire yedayili yokusika i-selicon powder ubungakanani kwaye ubungakanani bukhokelela kwi-adsorn kwi-adsorn verb, yenza ukuba kube nzima ukucoca. Ke ngoko, qinisekisa uhlaziyo kunye nomgangatho wokuphola kwaye unciphise umxholo we-powder kwifowuni epholileyo.

. Iseti epheleleyo yelayini, ukucheba kunye nokucheba kodaka kunomahluko omkhulu, ke inkqubo yokucoca ehambelana nayo, i-dosage yokucoca, ifomula, njl njl njl. Iarhente yokucoca yindawo ebalulekileyo, i-formula ye-sulaula ye-sulaula ecocekileyo, ialkalinity ayifanelekanga ekunciphiseni i-weire yedayisi, kufuneka ibe yeyokwakhiwa kwe-wicon wafer, i-arhente ye-arhente ejolise kuyo, kwaye ithathe Inkqubo yokucoca. Njengoko kuchaziwe apha ngasentla, ukwakhiwa kwe-arhente yokudimaka akufuneki kudaka.

.

Ukunciphisa ingxaki yokwenza iinwele ezimhlophe ze-velvet zivele

.

(2) sebenzisa iglue efanelekileyo yeGlue kunye nePlanethi yokunciphisa ungcoliseko lweSilicon Wafer;

.

.

. Kwangelo xesha, oko kunokwandisa ukuphuculwa kobushushu bamanzi, ukuhamba kunye nexesha kushishino lwangaphambi, ukuqinisekisa ukuba i-selicon powder ihlanjwe ngexesha

.

. (8) Kwinkqubo yokucoca isilicon wafer, ixesha livezwe emoyeni linokuncitshiswa kangangoko kunokwenzeka ukuthintela ukuveliswa kweentyatyambo kumphezulu we-silicon wafer.

.

. Umgaqo wayo uyafana nesisombululo sokucoca iSC1 (esaziwa ngokuba yi-fluiconductor i-semicon wafen wafen. Indlela yayo ephambili: Ifilimu ye-oxidition kwi-selicon Wafer ye-Slicon Wafes yenziwa yi-oxidation ye-H2O2, echithwe nguNah, i-Colosion yenzeka ngokuphindaphindiweyo. Ke ngoko, amasuntswana aqhotyoshelwe umgubo wesilika, i-resin, intsimbi, njl njl. Ngenxa ye-oxidation ye-H2O2, umcimbi oncediswayo kumphezulu we-waffered ugqitywe kwi-CO2, H2O kwaye ususiwe. Le nkqubo yokucoca ibingabavelisi baseSilicon Abafeli benkqubo yokuqhubela phambili ukucoca i-wiocry wan, i-silicon ye-silicon kunye nabanye abavelisi bebhetri. Kukho abavelisi bebhetri basebenzise inkqubo yokuqhubela phambili kwe-velvet ye velvet yangaphambili, nokulawula ngokufanelekileyo ukubonakala kwe-velvet emhlophe. Ingabonwa ukuba le nkqubo yokucoca yongezwa kwinkqubo yokucoca isilicon ye-selicon ye-selicon ye-selicon ye-selicon ye-salicon wall ukuya kuthi ga ngokusombulula ingxaki yeenwele ezimhlophe.

ukuqukumbela

Okwangoku, ukusika ucingo lwedayimani kube yeyona tekhnoloji yendlela yokuqhubela phambili kwe-crystal, kodwa kwinkqubo yokukhuthaza i-velvet ye-velvet kunye nemveliso yebhetri, ekhokelela kwiimveliso zebhayitri yedayisi I-Wafer inomchasi. Ngohlalutyo lothelekiso lwendawo emhlophe, kubangelwa yintsalela kumphezulu we-silicon wafer. Ukwenzela ukuba kuthintelwe ingxaki yesilika, eli phepha lihlalutya imithombo yongcoliseko lomphezulu weSilicon Afer, kunye namanyathelo okuphucula nemilinganiselo yokuphucula. Ngokwenombolo, ingingqi kunye nobume bendawo emhlophe, oonobangela banokuhlaziywa kwaye baphuculwe. Kuyacetyiswa ukusebenzisa i-hydrogen peroxide + yenkqubo yokucoca i-alkali. Amava aphumeleleyo abonakalisile ukuba inokuthintela ngokufanelekileyo ingxaki ye-wire yedayimani esisika i-selicon velvet yenza i-velvet imhlophe, kwisalathiso soshishino ngokubanzi kunye nabavelisi ngokubanzi.

Ixesha lokuposa: I-30 ukuya kwi-2024